Cutting Tools

Main text

SG Spiral Taps Short Chamfer

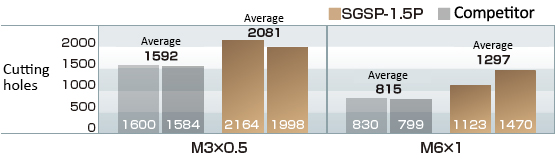

Optimization shape of chamfer can make tool life longer

Cutting performance of Short Chamfer (SGSP-1.5P)

| M3x0.5 Wear After 1600 holes | M6x1 Wear After 630 holes | ||

| Competitor | SGSP-1.5P | Competitor | SGSP-1.5P |

|

|

|

|

| Cutting condition | ||||||||

|---|---|---|---|---|---|---|---|---|

| Thread size | Thread depth | Drill Hole Dia | Cutting speed | Feed | Rotation | Work Material | Cutting Fluid | Machine |

| M3x0.5 | 6mm | Ø2.6 (Blind holes) |

30m/min | 1590mm/min | 3180min-1 | S50C (180HB) |

Water-soluble cutting fluid (External coolant) | Vertical Machining Center BT30 |

| M6x1 | 12mm | Ø5.1 (Blind holes) |

1591mm/min | 1591min-1 | Vertical Machining Center HSK63 | |||

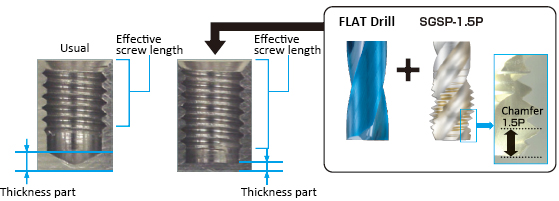

Securement of thin thickness and effective screw length are compatible, in combination with Flat drill

The minimum of a thickness part by using Flat drill

The maximum of effective screw length by using Short Chamfer screw threads