NACHI-FUJIKOSHI CORP.

Top page > Product Info. > Machine Tools > Skiving machining center for Gears > Skiving machining center for Gears GMS450

Machine Tools

Main text

Skiving machining center for Gears GMS450

Main specification

| Machining capacity | Max. workpiece diameter | mm | Ø450 |

|---|---|---|---|

| Max. machining module | — | m4.5 | |

| Max. machining teeth width | mm | 120 | |

| Max. workpiece height | mm | 250 | |

| Gear cutting tool | — | Skiving cutter | |

| Cutter spindle | Spindle taper hole (tool shank type) |

— | 7/24 Taper No.50 (BBT50) |

| Max. RPM of spindle | min-1 | 3000 | |

| Motor (30 min/continuous) | kw | 26/22 | |

| Workpiece spindle | Max. RPM of spindle | min-1 | 1400 |

| Motor (30 min/continuous) | kw | 26/22 | |

| Each unit traverse | Left – Right traverse (X-axis) | mm | 700 |

| Forward – Back traverse (Y-axis) | mm | 350 | |

| Up - Down traverse (Z-axis) | mm | 300 | |

| Tool swivel angle (B-axis) | deg | ±25 | |

| A.T.C. | Number of tool storage | piece | 6 |

| Max. tool diameter | mm | Ø150 | |

| Max. tool length | mm | 250 | |

| Tool selection method | — | Tool storage position fixed / random | |

| NC device | Type | — | FANUC 31i-B |

| Display | — | FANUC PANEL-i | |

| Utilities | Overall power used | kVA | 88 |

| Dimensions of machine | Machine height | mm | 2700 |

| Required floor space (width x depth) |

mm | 2500 x 3860 | |

| Net machine weight (main body) |

kg | 22000 | |

| Options | Workpiece chuck External scale 22 piece ATC Hard machining package Workpiece handling by robots |

||

Layout diagram

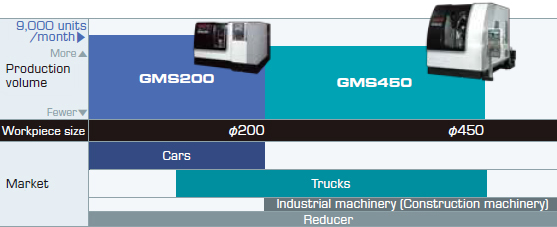

Product line-up for ring gear machining