Special Steels

Main text

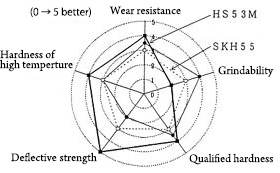

HS53M

Less crater wear and high cutting performance

HS53M : Co type HSS of outstanding wear resistance

Chemical Composition (%)

| NACHI Grade |

C | Si | Mn | Cr | Mo | W | V | Co |

|---|---|---|---|---|---|---|---|---|

| HS53M | 1.05 | 0.3 | 0.3 | 4.2 | 6.0 | 6.0 | 2.5 | 5.0 |

Applications

Hob, Borach, Ceiling cutter, Cutting die, Screw rolling mold

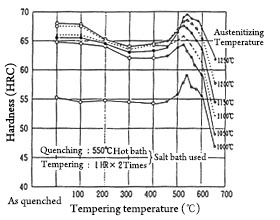

Heat treatment conditions

| NACHI Grade |

Annealing | Quenching | Tempering |

Practical hardness (HRC) |

|||

|---|---|---|---|---|---|---|---|

| Preheating | Austenitizing | Cooling | Temperature | Times | |||

| HS53M | 840°C |

820°C |

1210°C |

Gas, Oil | 540°C |

2 |

65 |

HS53M